Description

To Fit:

BMW 2′ M240i M240iX (G42) – Engine: B58 Gen2 – 2021 on

BMW 3′ M340i M340iX (G20 G21) – Engine: B58 Gen2 – 2018 on

BMW 4′ M440i M440iX (G22 G23 G26) – Engine: B58 Gen2 – 2021 on

BMW 5′ 540i 540iX (G30 G31) – Engine: B58 Gen2 – 2018 on

BMW 6′ 640i 640iX (G32) – Engine: B58 Gen2 – 2018 on

BMW 7′ 740i 745e (G11 G12) – Engine: B58 Gen2 – 2018 on

BMW 8′ 840i 840iX (G11 G12) – Engine: B58 Gen2 – 2018 on

BMW X3 M40iX (G01) – Engine: B58 Gen2 – 2018 on

BMW X4 M40iX (G02) – Engine: B58 Gen2 – 2018 on

BMW X5 40iX (G05) – Engine: B58 Gen2 – 2017 on

BMW X6 40iX (G06) – Engine: B58 Gen2 – 2018 on

BMW X7 40iX (G07) – Engine: B58 Gen2 – 2017 on

BMW Z4 M40i (G29) – Engine: B58 Gen2 – 2017 on

Background

The B58 engine, introduced with the F-series a few years back, has proven to be a real gem of an engine, capable of high outputs with great character. However, there are a few weak points that need addressing, both for performance and reliability. The B58 comes equipped with a water-to-air charge cooler that is coupled a with front-positioned heat exchanger (water radiator). The heat exchanger serves to cool the water circulating through the charge air cooler, which in turn helps dissipate heat from the charge air before it enters the engine. The charge air cooler is integrated into the intake manifold on the B58, making it an intricate and dense construction, demanding accuracy in the design and execution by us as an aftermarket producer.

Challenges with the factory components

Owners of tuned B58 engines often confront the issue of rapid heat soak in the charge air cooling system, particularly when the vehicle is used for track days. Elevated intake air temperatures may prompt the ECU to decrease the power output, or even switch the car into limp-home mode. Regular spirited street driving can also cause similar issues.

Additionally, the factory installed direct injection system, with its obvious benefits, is not well suited for high horsepower applications or ethanol flex fuel usage. To be able to inject more fuel, many turn to installing port fuel injector spacers between the intake manifold and the cylinder head. The downside with this solution is that it positions the injectors in a funny angle. As a result, the fuel hits the walls of the intake runners, leading to potential fuel puddling.

As is often the case, factory components can become limiting factors when you strive for high power levels, particularly in terms of airflow. The factory (OE) intake manifold is such a component, that not only restricts airflow but also poses a significant risk of cracking under high boost levels, due to its plastic construction.

The do88 solution

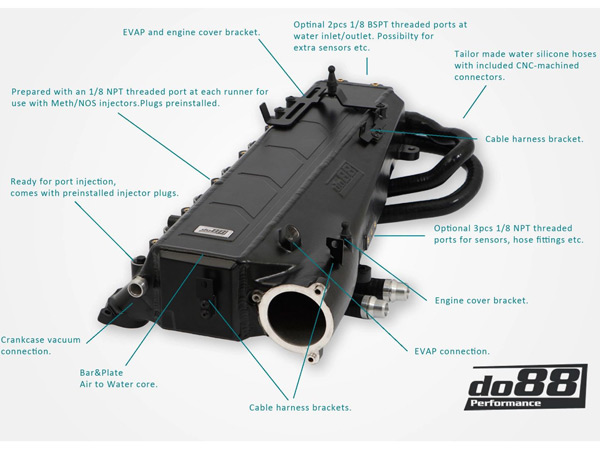

Bar&Plate core

Our manifold features a Bar&Plate design air-water core, which incorporates densely stacked cooling fins, offering great heat transfer. The core is precisely 102 mm (4 inches) thick, maximising its effectiveness for this specific application. Both the air and water fins´ characteristics have undergone careful evaluation to achieve the ideal balance between optimal cooling and airflow.

Innovatively designed cast end tanks

The charge air and cooling water are evenly distributed across the core through carefully designed, cast end tanks. The development of these end tanks involved a comprehensive process, including 3D-scanning, multiple design iterations followed by Computational Fluid Dynamics (CFD) analysis and 3D-printing, before arriving at the finalised prototype. We opted for cast end tanks over CNC-machining. Casting allows complex shapes that better serves the desired function. To us, maximum performance supersedes the bling factor!

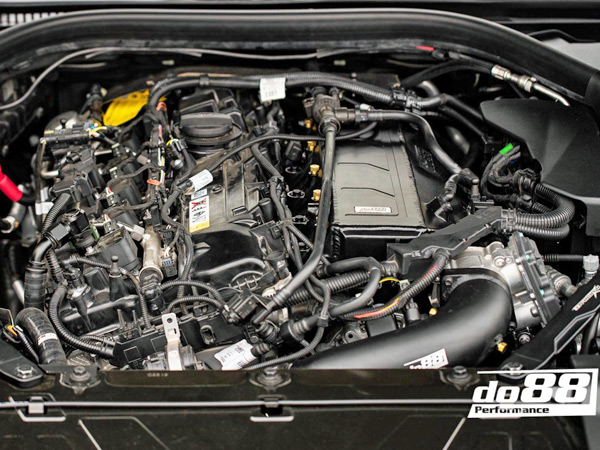

Engine Cover Compatibility

A key objective during the development of our do88 Charge Air Cooler, was ensuring its compatibility with the standard engine cover. It goes without saying, enthusiasts prefer to maintain the original appearance of their engine bay if possible. With this in mind, we invested significant effort to design a charge air cooler that not only makes a massive performance upgrade, but also fits beneath the engine cover. We even managed the challenging task of accommodating our auxiliary fuel rail under the engine cover. The devil is in the detail and to date, this unique feature sets the do88 kit apart from the competition. High performance builds tend to be made by enthusiasts that value the appearance equally as high as the sheer performance without compromise.

Key Features

Versatile Manifold Design: From Fuel Injection to Power Modifications

Our manifold outlet tank is pre-configured to accommodate auxiliary port fuel injection. A custom-made fuel rail with female AN-8 threads is available to purchase separately, this easily installs to the outlet tank. We designed it for compatibility with Injector Dynamics ID1050x-34-14 or Bosch EV14XK (short) fuel injectors. If you opt to not use port fuel injection, we provide injector blanking plugs for your convenience. Additionally, each cylinder runner on the outlet tank is equipped with a 1/8” NPT port, suitable for nitrous or methanol injection – a commonly used power modification for the B58 engine (sealing plugs are included).

Extra Measurement & Vacuum Ports

Integrated into the side of the manifold inlet tank, do88 has incorporated a 3-port pad directly into the casting. This feature offers the flexibility to measure additional parameters or serve as an extra vacuum source. Should you choose not to utilise these three 1/8” NPT ports, sealing plugs are provided in the included hardware kit.

Two 1/8” BSPT ports are strategically positioned on the top of the rear water tank. These ports serve dual functions. They can be used for monitoring both inlet and outlet water temperatures, but also act as bleeding ports to assist in the air-bleeding process, ensuring that all air is effectively purged from the intake manifold. For your convenience, 1/8” BSPT plugs are provided in the included hardware kit.

Advanced Thermal Management

Included with the intake manifold is a special thermal barrier spacer, engineered to insulate the aluminium intake manifold from conductive heat transfer from the cylinder head. This barrier effectively lowers intake air temperatures (IAT´s), enhances the efficiency of the charge air cooler, and helps minimise the issue of heat soak. Unlike the OE plastic intake manifold, the do88 manifold is made from aluminium, capable of withstanding higher boost pressures. The thermal barrier spacer reduces the conductive heat transfer, otherwise typical to aluminium components. The spacer features a robust seal, achieved through custom-made, high-specification FKM-silicone O-rings. These O-rings are installed in precision-machined grooves for a secure fit. This approach offers a significantly better seal compared to other competitors´ methods, which often rely on less reliable sealing agents.

Product Details:

Utilises a high performance, Bar&Plate, air-to-water intercooler core, 102 mm (4”) thick. 11 water cooling rows, OE 6 rows.

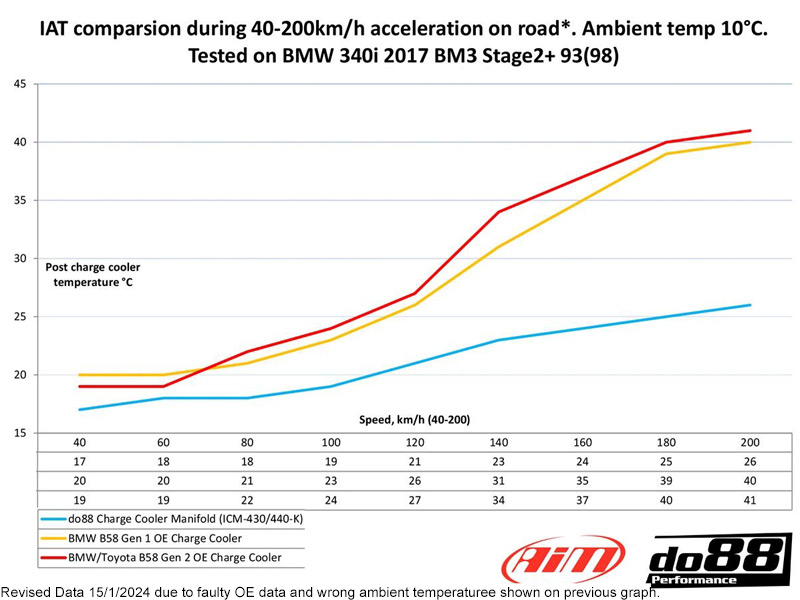

Lower inlet air temperature under identical conditions: 26°C compared to OEM 34°C. Exact figures to be found in the diagrams under the product pictures.

More air to your engine, less backpressure and better airflow! Airflow at 0,1 bar / 1,45 psi pressure drop: 873 CFM (595 CFM), 47% higher! See diagram under the product pictures.

Peak powergain of 5 hp! Measured on car with bootmod3 Stage 2+ (BMW 340i 2017).

Highest midrange powergain of 18 hp!

Highest torque gain of 28 Nm!

Designed in SolidWorks using Computational Fluid Dynamics (CFD).

Easy access to spin-off oil filter for quick oil changes – no need to remove the manifold every oil change.

Integrated sensor pad with three 1/8″ NPT ports to measure additional parameters (sealing plugs are included).

Optional fuel rail (not included) for auxiliary top feed port injection.

Injection plugs for each cylinder runner is included.

Individual 1/8″ NPT ports on the top of each cylinder runner for nitrous or meth injection (sealing plugs are included).

Individual 1/8″ BSPT breather ports for both inlet/outlet water connections on the back of the manifold for an easy air-bleeding of the system (sealing plugs are included).

Plug-and-play design, requiring no modifications to install.

Included are all the essential brackets needed for various components, such as wire harnesses and the engine cover.

Can be installed with OE or aftermarket engine covers (with OE connections). It even fits with small modification when running with the auxiliary port injection fuel rail.

Thermal barrier spacer included, engineered to insulate the aluminium intake manifold from conductive heat transfer from the cylinder head.

Custom made high spec FKM-silicone O-rings included for both the thermal barrier spacer and intake manifold (12 pcs in total).