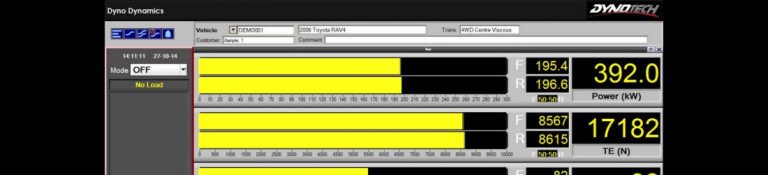

Dyno Dynamics Dynotech 1200HP Chassis Rolling Dyno

Our in house state of the art 2WD rolling road / dynamometer facilities allow us to tune cars in a safe and controlled environment, enabling us to carry out in depth diagnostics without the concern of speed limits or traffic conditions out on the public road, while producing accurate and repeatable results.

We can run front or rear wheel drive vehicles, and can even cater for certain 4wd vehicles (Haldex based drivetrains can typically be disabled allowing us to run them on our 2WD setup)

To ensure safe running we monitor and log the Air to Fuel ratio and Boost pressure at all times, these can be plotted on the graphs if required. Additional OBD data logging can be carried out with more than 150 alternate channels of data available

- Single Measures power from 1HP (0.75kW) up to 900KW (1200HP)

- Measures axle torque up to 6250 Nm

- Max speed 250 km/h

- Steady State graphing

- Command RPM Dynotech user friendly windows based software-Auto saves your data, no need for you to manually save.

- Auto Weather Station automatically compensates for temperature, pressure, humidity variations.

- OBD II Kit can stream data from ECU into Dynotech software

- Get the optional mobility wheel kit to make your dyno portable, so you can move it around your workshop or take it out for mobile dyno tuning

- Smaller size allows convenience of positioning in both smaller workshops and home garage

- Unique DD knurling- Our knurling process makes sure that our rollers are non-aggressive on tyres and closely mimic the road experience

- Our software has been designed by our own experienced software engineers in our Melbourne Manufacturing Facility- no joint ventures! We own it, we service it and we constantly work to enhance and improve our firmware and our software

- All our Dynos are modular upgradable. Your dyno will never be out of date

- Our dynos are designed, developed, engineered manufactured and assembled by our highly skilled team in our factory in Melbourne Manufacturing Facility, Victoria, Australia

- The only accurate power comparison on dynamometers

- Shootout mode is where the software locks in the ramp rate and other parameters for the individual vehicle. This information is then recorded on the graph printout and enables everyone to see the conditions that the dyno was operated under. Shootout allows accurate power comparisons between different Dyno Dynamics shootout enabled dynamometers. It can also provide you with flywheel power and engine torque figures.

Custom Channels (EDM Support)

Allowing in conjunction with the pro tuners software the facility to use these inputs for any 0 – 5 Volts signal/input and then to calibrate, rename, data log or graph the sensor. These can be used for knock sensors, throttle position switches, oxygen sensors, fuel pressure, fuel flow or any other output from the vehicle.

A perfect way to demonstrate the sensor in a graph or wave form, live on the monitor.

Scripting

Scripting enables you to create automatic test for the dynamometer

These tests can:

- Prompt the operator with on screen messages

- Guide operator with on screen targets for Power, Load or Speed

- Automatically set controls for Dyno Speed / Load / Ramp

- Records information in the Snapshot data file

- Run an emission drive cycle test with a gas analyser