It has been long debated whether or not the injectors fitted as standard to the Corsa VXR and similar engines are suitable for tuning. It’s been our long standing opinion that if you tune a car you use sensors and injectors which are suitable for the power you’re looking to run. So under that note, we will not tune a Corsa VXR beyond a soft stage 1 without uprated injectors fitted.

An injector has a certain amount of flow rate, this describes the amount of fuel it can flow in a set period of time. The injectors works by pulsing a valve open and closed very rapidly to squirt a very measured amount of fuel into the engine. The injector duty cycle is the amount of time this valve is open for verses the maximum possible amount of time available.

The maximum time an injector has is limited by the cycle of the engine; from the moment the intake valve closes the injector can start to fill the inlet port with fuel ready for the next cycle. As the engine nears the next cycle the inlet valve will open and the fuel will be consumed into the cylinder. The injector then has until the moment the inlet valve closes again to inject the last part of the required fuel – once this valve is closed no more fuel can get into the cylinder for this cycle and anymore will be contributed to the next engine cycle. If it’s not enough then the engine will run leaner than desired.

The exact amount of fuel required is determined by measuring the amount of air coming into the engine using the MAF sensor. The MAF sensors air reading is then divided up by the number of cylinders and the number of cycles the engine is completing in a set time.

For example your MAF sensor may read 1000 grams of air per second coming into your engine. The engine may be a 4 cylinder and rotating at 3000rpm. This means that the engine would be completing 25 cycles a second as it takes 2 revolutions to complete a cycle of all cylinders. So this 1000g of air will be divided by 25 cycles giving 40g per cycle and then divided by the number of cylinders giving 10g of air per cylinder per cycle.

The amount of fuel required then depends on the air fuel ratio you request the injector to provide. The air fuel ratio is merely how many parts of air to how many parts of fuel, a richer mixture with more fuel will require a longer injector on time, or pulse than less fuel or a leaner mixture. The correct air fuel ratio is important on a petrol engine, too rich you will bog down on power, cause smoke from the exhaust or risk bore wash inside the engine, too little and you could risk excessive uncontrolled cylinder temperatures leading to knock or damaged engine components.

Going back to our example, if you run the engine at 14.7:1 then it will only require 0.68g of fuel. If you however needed to run the engine richer at say 11.5:1 which is a very safe rich ratio it would then be required to deliver 0.87g of fuel to the cylinder for the same amount of air.

The exact point an injector runs out of capacity will depend on the level of power you wish to run and also the air fuel ratio you wish to use to make this power. Running a car a bit leaner at say 12.5:1 will lower the fuel requirement and make good power, but with less excess fuel for cooling the engine runs hotter and potentially more damage could occur.

If you run richer at around 11.5:1 the car will run cooler and much safe but you will use more fuel and your injector will max out sooner at a lower power output. The faster the engine rotates the less time each injector has to fill the cylinder with the required air, this is why the more you rev the engine the higher the duty cycle of the injector will be.

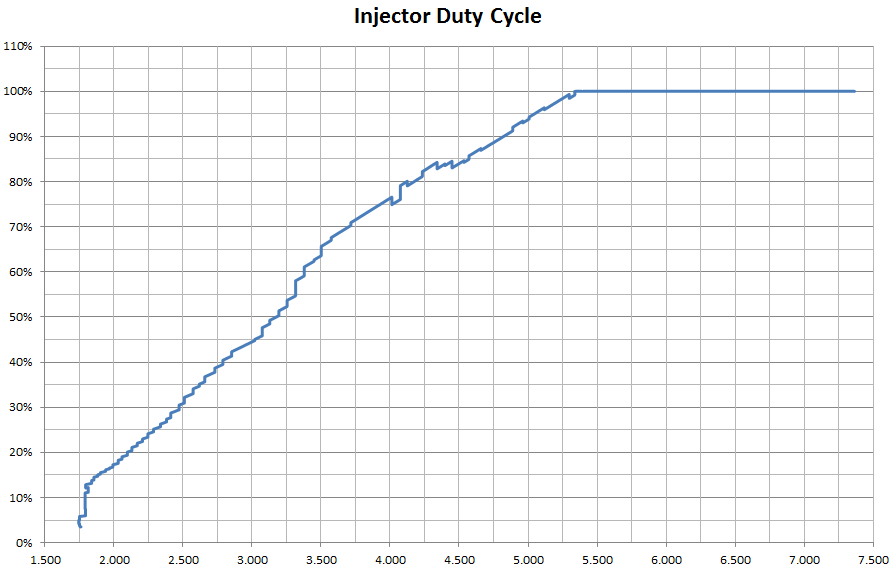

You can monitor your injector duty cycle by recording the engine speed and the injector pulse width with products such as opcom. You can then take this log and run it though a simple equation to calculate the duty cycle.

Injector Duty Cycle = Injector Pulse / (120,000 / RPM)

By using this equation you can see that a number of third party stage tuned Corsa’s do in fact max their injectors but not only at the top end but for a considerable part of the rev range, sometimes as low as 5000rpm.

This graph was taken from a car running a map from a well known third party handheld home tuning tool. The supplier has previously promised that the injectors do not run to their maximum on maps they provide with the tool but a simple data log shows otherwise.

The above mentioned car was running air fuel ratios in the region of 12:1 through the mid range but 12.5:1 by the top end. The map in fact requested the air fuel ratio to be 11.8:1 under normal conditions and allowing up to 11:1 under high temperature conditions. Despite the map being set to request this, it is physically impossible for the car to add anymore fuel beyond 5,500 rpm therefore running considerably leaner than desired.

You should select an injector that is suited to run no more than around 85% duty cycle, this gives you capacity to allow the ECU to increase the fuel mixture to a richer ratio in order to provide extra cooling when things get hot. It also means as injectors get older and potentially clogged your fuel trims have the ability to adjust and increase the required pulse width to compensate. Finally on some ECU’s their injector driver circuits or injectors own coils, can be damaged by leaving the coil energized permanently, though this doesn’t appear to be an issue for this particular car.

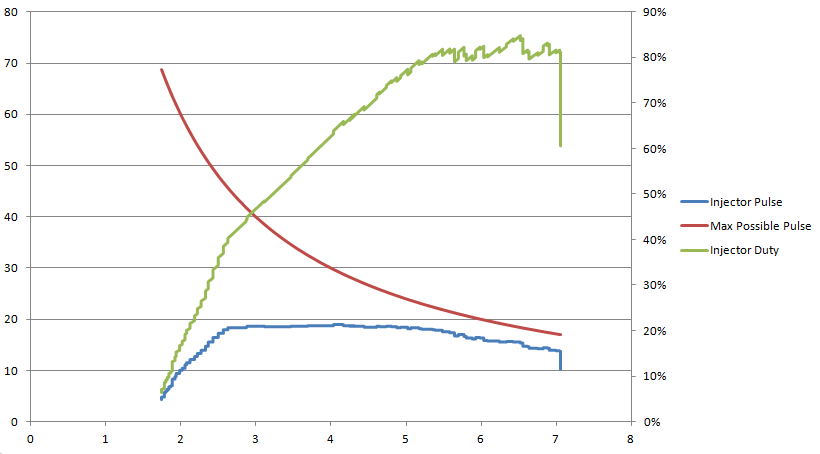

Here is a WGM Motorworks Stage 3 Corsa VXR with our 395cc, showing 83% max duty.

Finally the most import thing to remember with injectors is they must suit the software on the ECU. This means you cannot just fit an injector without a suitable remap. If the ECU map is not calibrated with the correct constant valves for the injectors characteristics the ECU will be able to properly control the injector and damage to your engine may well occur.

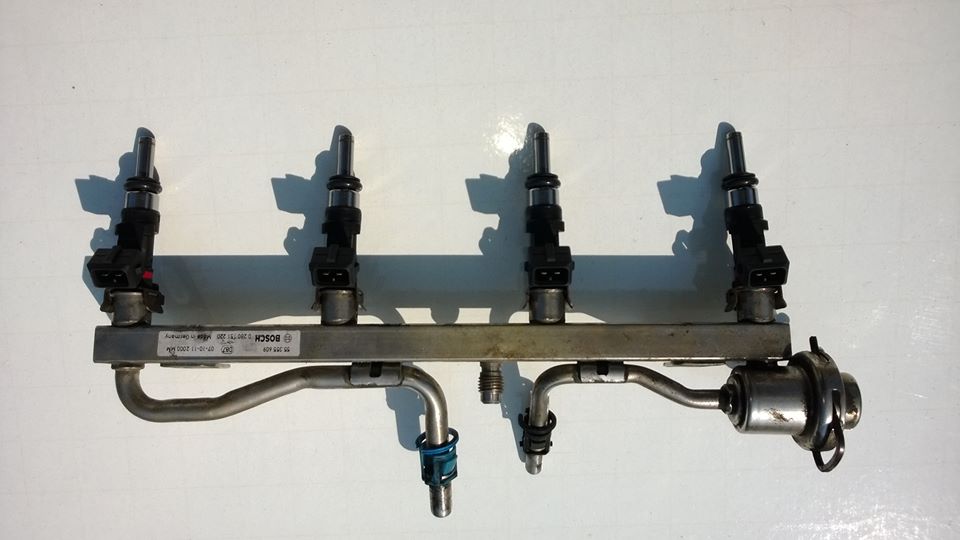

At WG Motorworks we can supply and fit a number of injector types to the car suitable for a range of different power levels. We can supply injectors that are direct fit which require no machining or reworking of the inlet manifold. We also do not require adjustable regulators as we are able to correctly map the injector selected precisely using the standard regulator.

We recommend the following injector sizes:

395cc for up to 270bhp

540cc for up to 370bhp

630cc for up to 420bhp.

We can supply and fit the injectors as well as provide a calibrated remap for the injector, or we can re-calibrate existing remaps from third parties if you wish to add piece of mind by fitting injectors.